Bismuth bronze is a versatile alloy with a wide range of applications, primarily due to its lead-free composition, good machinability, and corrosion resistance. Here are some common ways bismuth bronze is used:

Plumbing and Waterworks:

- Faucets and fittings: Its lead-free nature makes it ideal for components in contact with drinking water, complying with regulations like the Reduction of Lead in Drinking Water Act.

- Valves and pumps: Bismuth bronze’s strength and corrosion resistance ensure reliable performance in water systems.

- Pipe fittings: Durable and safe for potable water, bismuth bronze fittings are used in residential and commercial plumbing.

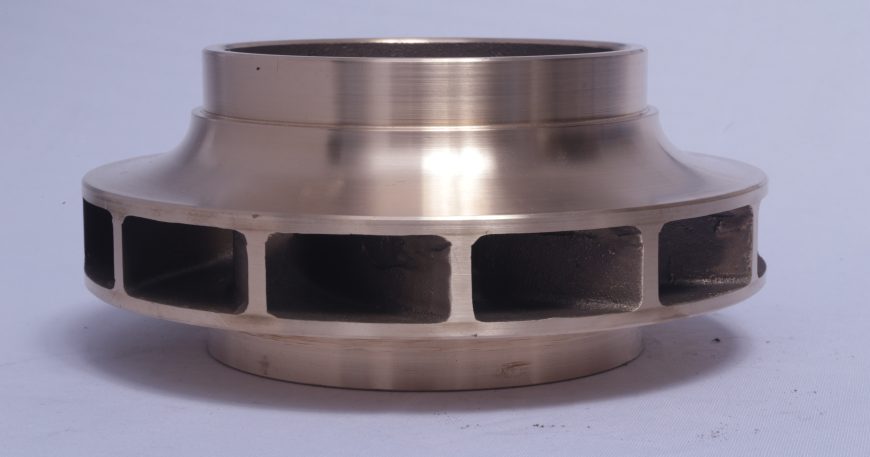

- Water pump impellers: The alloy’s resistance to wear and corrosion makes it suitable for pump components.

Industrial Applications:

- Bearings and bushings: Bismuth bronze offers good wear resistance and lubricity, making it suitable for bearing applications.

- Gears and other machine parts: Its machinability and strength allow for the production of complex parts.

- Housings and structural components: Bismuth bronze can be used for structural elements requiring corrosion resistance.

Other Uses:

- Decorative items: The alloy’s attractive appearance and ability to hold a polish make it suitable for decorative applications.

- Musical instruments: Some musical instrument components may be made from bismuth bronze.

- Marine applications: Its corrosion resistance makes it suitable for use in marine environments.

Advantages of Bismuth Bronze:

- Lead-free: Environmentally friendly and safe for use in contact with drinking water.

- Good machinability: Easy to machine into complex shapes.

- Corrosion resistance: Suitable for use in harsh environments.

- Good wear resistance: Offers durability in moving parts.

- Attractive appearance: Can be polished to a high sheen.

Overall, bismuth bronze is a versatile material with a wide range of applications, particularly in plumbing and industrial sectors where its lead-free composition and performance characteristics are valued.

Key properties:

- Lead-free

- Good machinability (70% compared to free-cutting brass)

- Good polishing and plating characteristics

- Better castability at lower temperatures

- Superior microstructural characteristics

Applications:

- Faucets

- Housings

- Small gears

- Pipe fittings

- Plumbing goods

- Pump components

- Water pump impellers

Chemical composition:

- Copper (Cu): 85.0 – 89.0%

- Tin (Sn): 6.0 – 7.5%

- Lead (Pb): 0.09% max

- Zinc (Zn): 2.0 – 4.0%

- Iron (Fe): 0.20% max

- Nickel (Ni): 1.00% max

- Antimony (Sb): 0.35% max

- Phosphorus (P): 0.10% max

- Sulfur (S): 0.08% max

- Aluminum (Al): 0.005% max

- Bismuth (Bi): 1.7 – 2.7%

- Silicon (Si): 0.005% max

Mechanical properties:

- Tensile strength: 30 ksi (207 MPa) min

- Yield strength: 14 ksi (97 MPa) min

- Elongation in 2 in. or 50 mm: 6% min

Physical properties:

- Melting point – liquidus: 1855°F (1012°C)

- Melting point – solidus: 1445°F (785°C)

- Density: 0.321 lb/in3 at 68°F (8.89 gm/cm3 at 20°C)

- Specific gravity: 8.89

- Electrical conductivity: 14.5% IACS at 68°F (0.084 MegaSiemens/cm at 20°C)

- Thermal conductivity: 38.0 Btu·ft/(hr·ft2·°F) at 68°F (65.8 W/m·°K at 20°C)

- Coefficient of thermal expansion: 10 x 10-6 per °F (68-392°F) (17.3 x 10-6 per °C)

- Specific heat capacity: 0.093 Btu/lb/°F at 68°F (389.6 J/kg·°K at 293°K)

- Modulus of elasticity in tension: 16,900 ksi (116,522 MPa)

Fabrication properties:

- Soldering: Excellent

- Brazing: Good

- Oxyacetylene welding: Not recommended

- Gas shielded arc welding: Not recommended

- Coated metal arc welding: Not recommended

Equivalent specifications:

- CDA C89835

- UNS C89835

- B04 bronze

- Lead-free bronze

- Bismuth bronze

- Copper-bismuth bronze

- Lead-free bismuth bronze

- Bismuth tin bronze

- Lead-free bismuth tin bronze