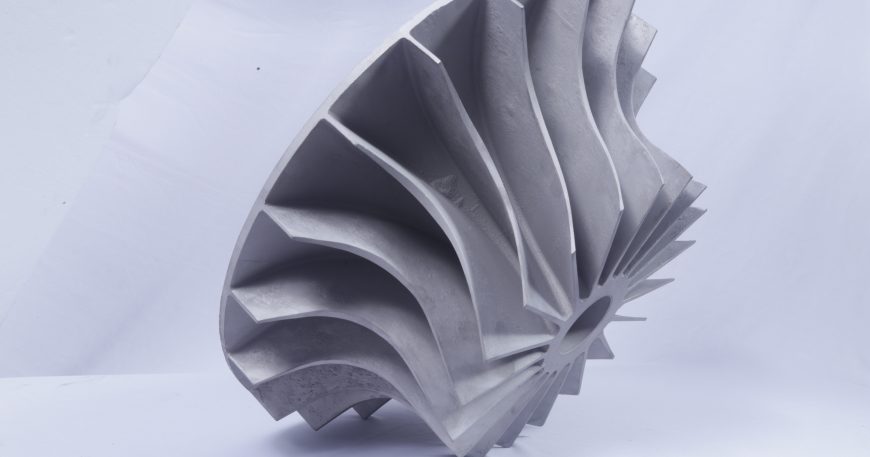

Aluminium pressure die casting is a widely used manufacturing process for producing high-quality, complex-shaped parts from aluminum alloys. It involves injecting molten aluminum into a steel mold (die) under high pressure, resulting in rapid solidification and the formation of a solid part. This process is known for its efficiency, precision, and ability to produce large volumes of parts with consistent quality.

Process Overview:

- Die Preparation: The die, typically made of hardened steel, is designed to the exact shape of the desired part. It consists of two halves: a stationary half and a movable half. The die cavity is often coated with a lubricant to facilitate part ejection and improve surface finish.

- Melting and Injection: Aluminum alloy ingots are melted in a furnace until they reach the desired temperature. The molten aluminum is then transferred to a shot sleeve, where a piston injects it into the die cavity under high pressure.

- Solidification and Ejection: The molten aluminum solidifies rapidly under pressure, taking the shape of the die cavity. Once solidified, the die opens, and ejector pins push the casting out of the die.

- Trimming and Finishing: The ejected casting may require trimming to remove excess material, such as runners and gates. Additional finishing processes, such as machining, surface treatment, or painting, may be performed to meet specific requirements.

Advantages of Aluminum Pressure Die Casting:

- High-volume production: Die casting is ideal for producing large quantities of parts quickly and efficiently.

- Complex shapes: The process allows for the creation of intricate and complex shapes with fine details.

- Dimensional accuracy: Die-cast parts exhibit high dimensional accuracy and repeatability.

- Excellent surface finish: The high pressure injection results in a smooth and consistent surface finish.

- Lightweight: Aluminum alloys offer a good strength-to-weight ratio, making die-cast parts lightweight yet durable.

- Cost-effective: Die casting can be a cost-effective manufacturing solution for high-volume production runs.